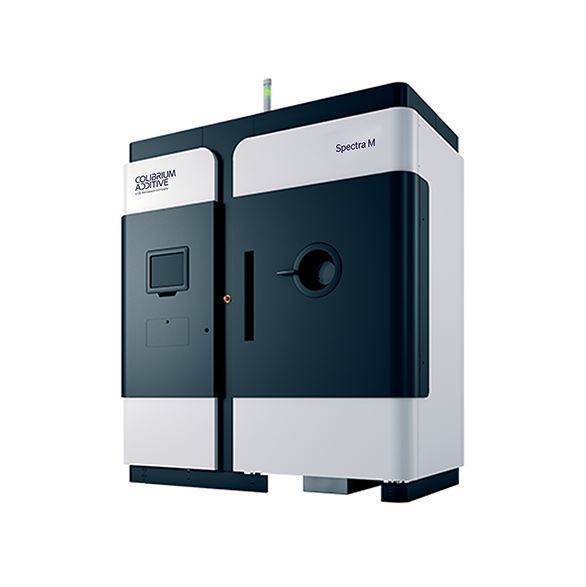

Spectra L

The Spectra L offers the largest build volume of our EB-PBF machines, allowing enhanced capacity to produce large, high-integrity parts, faster than ever before. quality.

The key

to higher productivity

The Spectra L allows for mass production of parts by offering the unique EB-LPB feature to tightly stack parts without compromising on quality. Electron Beam Powder Bed Fusion (EB-PBF) technology provides you with design freedom and allows you to build free-floating parts in semi-sintered powder. Any supports are primarily used for heat equalization and are easily removed when the build is finished.

Spectra L's improved melt process results in enhanced surface finish and consistent material properties for thin and bulky geometries. This provides the freedom to design parts without limiting your imagination. In addition, the Spectra L offers the largest build volume of our EB-LPB machines, allowing enhanced capacity to produce high-integrity parts, larger and faster than ever before.

Spectra L's improved melt process results in enhanced surface finish and consistent material properties for thin and bulky geometries. This provides the freedom to design parts without limiting your imagination. In addition, the Spectra L offers the largest build volume of our EB-LPB machines, allowing enhanced capacity to produce high-integrity parts, larger and faster than ever before.

Point Melt technology

EBM Point Melt is a process in which metal powder is melted point by point instead of the usual lines. This technology allows for more accurate temperature control and reduces temperature gradients during the printing of a part. As a result, metal parts made with point melt can benefit from improved surface quality and simpler support structures. Point melt also allows for additional scanning strategies, such as multiple exposures of the same area, which allow better control of the resulting microstructure, especially in the z-direction.